-

Roper Progessing Cavity Pump Package

Powerflo Products Inc. designs quality Roper Progressing Cavity pump and motor packages custom built and engineered to meet your specific pumping conditions and requirements.

Please contact us for pump packages to meet your existing or new application.

Packages Shown in Picture:

2 Roper 72202GHL Pump units, Belt Driven, each with a Leeson Motor, L-shape base plate configuration and OSHA style belt guard. -

Roper Progessing Cavity Pump Package

Powerflo Products Inc. designs quality Roper Progressing Cavity pump and motor packages custom built and engineered to meet your specific pumping conditions and requirements.

Please contact us for pump packages to meet your existing or new application.

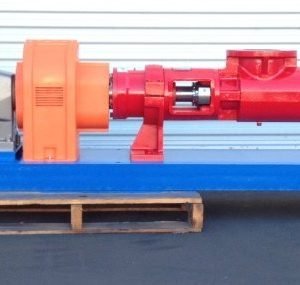

Package Shown in Picture:

Roper 73228GHL Pump fitted with a John Crane Cartridge Seal with Tungsten Carbide v. Silicon Carbide faces. The pump is driven in-line by a Nord Gear reducer at a speed to yield 100GPM of crude oil, water, sludge, mixture with 5% solids. Powered by a 30HP motor, this 3 stage pump is easily capable of pumping the thick and abrasive fluid while meeting the system’s required 175PSI discharge pressure. Pump size and speed is carefully selected to match the operating conditions and give durable and long stator and rotor life. Pump, reducer, and motor are all flexibly coupled with OSHA approved coupling guards.

800-758-4788 |CONTACT US

Progressing Cavity Pump Units

© Copyright 2016. All Rights Reserved.