-

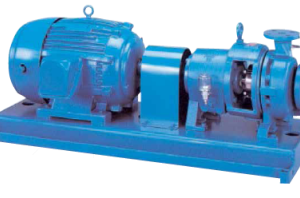

Aurora Pumps – 344A Flexible Coupled Centrifugal Pumps

344A Aurora Pumps are available in various sizes and materials of construction as shown below:

- 344A-BF – Cast Iron Bronze Fitted

- 344A-AI – All Iron

- 344A-AB – All Bronze

-

Aurora Pumps – ANSI Regenerative Turbine Pumps

Powerflo Products Inc. designs and builds quality centrifugal ANSI pump and motor packages custom built and fabricated in our Cypress, California facility. Each unit is engineered for high reliability and efficiency while meeting your application’s pumping conditions and requirements.

-

Aurora Pumps California Distributor

Powerflo Products Inc. is a proud distributor of Aurora Pumps for California . Their line up of centrifugal pumps have served California with reliable and efficient pumping for decades. Many centrifugal pump designs are available including the following: ANSI, End Suction, Vertical Inline, Double Suction Split Case, Regenerative Turbine, Vertical Multi-Stage and Vertical Turbine.

Please contact our team at Powerflo for assistance with existing pumps and new application. As the authorized Aurora distributor and repair facility we can provide an efficient solution for your pump and process needs. We’re excited to help!

-

Bear Cat Truck Pump

Roper Gear Pump Model for Asphalt Emulsion

These Roper Pumps are IN STOCK at Powerflo and ship same or next day for rapid delivery or pick up! No more pumps “made to order.” Keep your Bear Cat Truck in service now!

- Includes: 2-4″ NPT Flanged Ports, Teflon Packing, Bronze Bushings, Non-Jacketed, with Built In High PSI Relief Valve

- Heavy Duty Cast Iron Helical Gear Pump

- Speeds to 900 RPM, Flows to 468GPM

- Same dimensions as Bear Cat pumps

-

Centrifugal ANSI Pump Packages

Powerflo Products Inc. designs and builds quality centrifugal ANSI pump and motor packages custom built and fabricated in our Cypress, California facility. Each unit is engineered for high reliability and efficiency while meeting your application’s pumping conditions and requirements.

Please contact us for pump packages to meet your existing or new application.

-

Chesterton 1400R Carbon-Reinforced Graphite Packing

Chesterton 1400R Carbon-Reinforced Graphite Packing:Reinforced, braided, graphite packing with a corrosion inhibitor. The carbon yarn reinforcement is provided within the graphite tape yarn as well as the braided construction.

- 1400R forms a homogeneous mass under gland pressure, so that leakage cannot penetrate the packing set.

- The all-carbon/graphite set withstands higher shaft speeds while limiting shaft friction.

- The structural carbon fiber reinforcement prevents extrusion when 1400R sets are installed in valves at higher pressures.

In addition to its excellent sealing capabilities in rotating equipment, 1400R is a superior valve sealing material. This dual purpose design makes it a truly universal mechanical packing.

Features & Benefits

- Passive molybdate-corrosion inhibitor

- Forms a homogeneous mass under gland pressure

- For use in valves and pumps

-

Chesterton 1510 General Duty Single Cartridge Seal

Simple Installation and Increased Reliability Plant-wide in General Duty Applications

Maximize maintenance efficiency and increase plant productivity with the 1510 Single Cartridge Seal. Designed to fit process equipment plant-wide by incorporating Chesterton T.A.B.S. (Tapered Adjustable Bolting System) the compact profile makes seal installation easy.

Reliability through temperature variations and intermittent operations is ensured with the use of monolithic seal faces and true non-fretting construction. Impeller adjustments after seal fitment are accommodated with the unique resettable centering strap, even when adjustment is required between routine maintenance. Incorporating Chesterton’s 5 key features of good mechanical seal design, the Chesterton 1510 sets the new standard for general duty cartridge seals.

Features:

- Reliable through temperature cycling and intermittent process with monolithic seal faces

- In service impeller adjustment is possible with the unique centering strap

- Mounts easily on various types of rotating equipment using Chesterton T.A.B.S.

- Prevents damage to your equipment and internal components via true non-fretting design

-

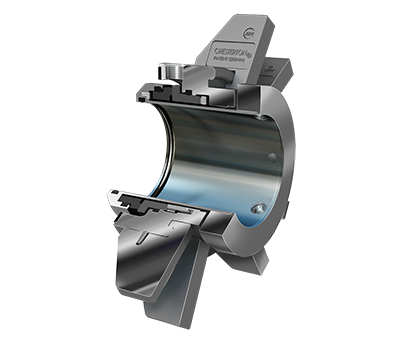

Chesterton 155 & 255 Standard Cartridge Single Seal

The Chesterton 155 cartridge-style single seal is the perfect seal for all of your general-purpose plant applications. This simple mechanical seal design results in a more robust and reliable seal for general applications, while the low profile seal faces allow for low heat generation—making it ideally suited for non-lubricating fluids.

With the addition of the adjustable gland tabs, the Chesterton 155 can adapt to any bolting pattern, making installation easier.

Features:

- Adjustable/removable gland tabs

- 360-degree flush port rotation

- Quick-release centering straps

- Available in special alloys

- Dynamically stress-relieved narrow profile faces

The Chesterton 255 cartridge-style double seal provides a cost-effective solution for a wide variety of applications that require dual sealing with the flexibility to meet some of the most challenging conditions.

Thanks to its integrated pumping ring and universal gland with both flush port as well as quench and drain, the 255 can handle the most demanding applications. Whether you need advanced environmental controls or system pressure fluctuation tolerance, the 255 has you covered.

Features:

- Geometric double balance eliminates shifting O-Rings

- High-flow pumping device

- Features from brochure

- Self-Centering Lock Ring™ eliminates misalignment

-

Chesterton 170 Slurry Single Cartridge Seal

Engineered for harsh, heavy consistency slurry environments, this seal’s unique, no-clog design reduces or eliminates costly external seal flushes. The Chesterton 170 improves plant efficiencies by reducing product dilution and increasing production rates.

170 ISO is an off-the-shelf product that fits directly to ISO-3069-H and ISO-3069-C seal chambers.

Features:

- Runs longer in heavy abrasive slurries without the need for flush or quench water

- Non-clog pressure plate design

- Springs located entirely outside the seal

- Simple, robust design

- Micro-polished seal faces

- Optimal balance for slurry service

- Easy to maintain

-

Chesterton 170L Slurry Cartridge Single Seal

Engineered to operate in harsh, heavy consistency slurry environments and eliminate costly external seal flushes in the majority of applications.

Chesterton 170L is designed for sealing mineral-based process materials such as ores, limestone, coal, sugar, and phosphates. The innovative, non-clog seal uses a unique coil spring design in which the springs are located entirely outside the seal. It is engineered to fit Warman® AH® series pumps without modification.

The 170L uses a single clamping screw which simplifies seal removal in sticky or viscous fluids or where solids clog up the set screws. This seal has large clearance and rugged components designed to resist the effects of heavy slurry environments.

Features:

Runs longer in heavy abrasive slurries without the need for flush or quench water

-Non-clog pressure plate design

-Innovative pressure plate design

-Springs located entirely outside the seaReliable design that addresses real life slurry pumping conditions

-Micropolished O-Ring surfaces eliminate O-Ring hang-up

-Optimal balance for slurries

-Line-to-line slurry faces

-Stationary springs

-High strength drivesEasy to maintain

-Single clamping screw simplifies seal installation and removal

-Integrated centering tabs

-Washable in-service

-In-field repairable

-No quench and drain needed -

Chesterton 1725A Food Process Packing

Chesterton 1725A Food Process Packing is constructed with expanded PTFE yarn and a specially-designed lubricant to provide superior sealing capability in rotating equipment. Its interbraid construction ensures maximum strength as well as minimal wicking of fluid through the packing.

Chesterton 1725A complies with the USDA requirements for minimal food contact and FDA specification 21 CFR, 178.3297, 177.2800, and 177.1550. This packing has been approved by NSF International; it meets the requirements of Standard 61 for use in potable drinking water systems, as well as the ACS Certification for drinking water.

1725A is applicable for use in pumps, agitators, mixers, and other rotary and reciprocating equipment.

Features & Benefits- Meets USDA requirements for minimal food contact

- Meets FDA requirements 21 CFR 178.3297,21 CFR 177.2800,21 CFR 177.1550

- Approved by NSF/ANSI and ACS standards for use in drinking water systems

- Completely inert to most materials

- Handles high shaft speeds

-

Chesterton 1727 Multi-Lon Synthetic

Chesterton, 1727 Multi-Lon® is a synthetic packing designed specifically for general service pump applications. It is able to deliver performance equal to synthetics with the pliability of asbestos. Unlike the first generation of synthetic packing, Multi-Lon does not suffer from limitations that prevent general service use. Multi-Lon consists of inter-braided, continuous, synthetic thermoset fibers immunized with PTFE lubricant and a special silicone-free, break-in, sacrificial lubricant.

- Unlike many synthetic yarns, it does not cause severe scoring

- Does not cause electrolytic pitting like carbon or graphite yarns

- Does not have the shaft speed limitations or the elongation/ extrusion problems often associated with PTFE fiber yarns

1727 Multi-Lon Benefits & Features:

- High chemical resistance

- Long-wearing for fewer repacks

- Non-staining; protects product quality

- Non-hardening for fewer adjustments

- Non-abrasive; less sleeve wear

- Non-pitting; saves shafts

800-758-4788 |CONTACT US

Product Tag - RFQ Only

© Copyright 2016. All Rights Reserved.